BMS (Battery Management System) is a system to detect the status of Li-ion batteries and control the charge and discharge promptly to keep the operation safe and extend battery life. Without BMS, Li-ion batteries may damage or explode due to improper use.

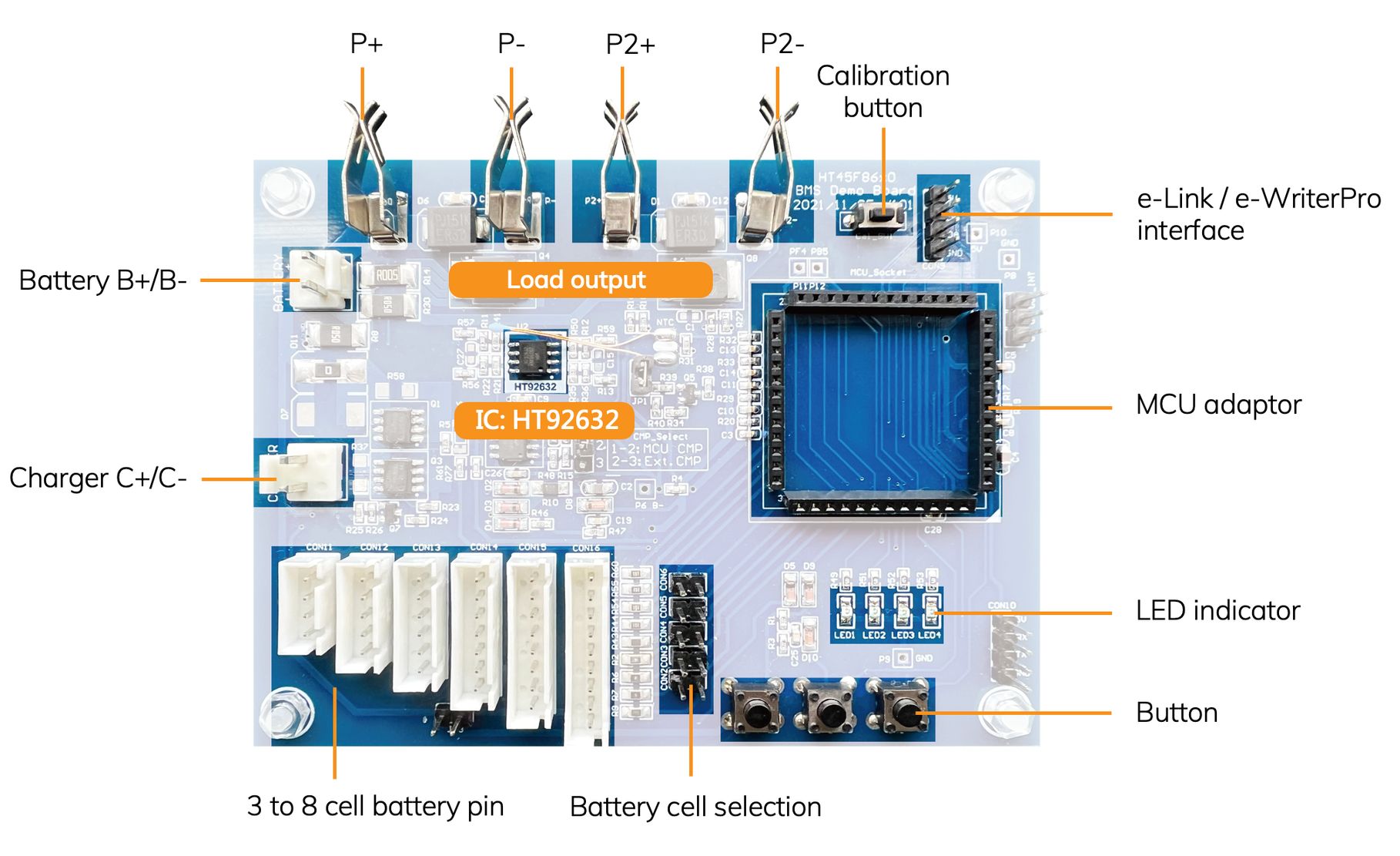

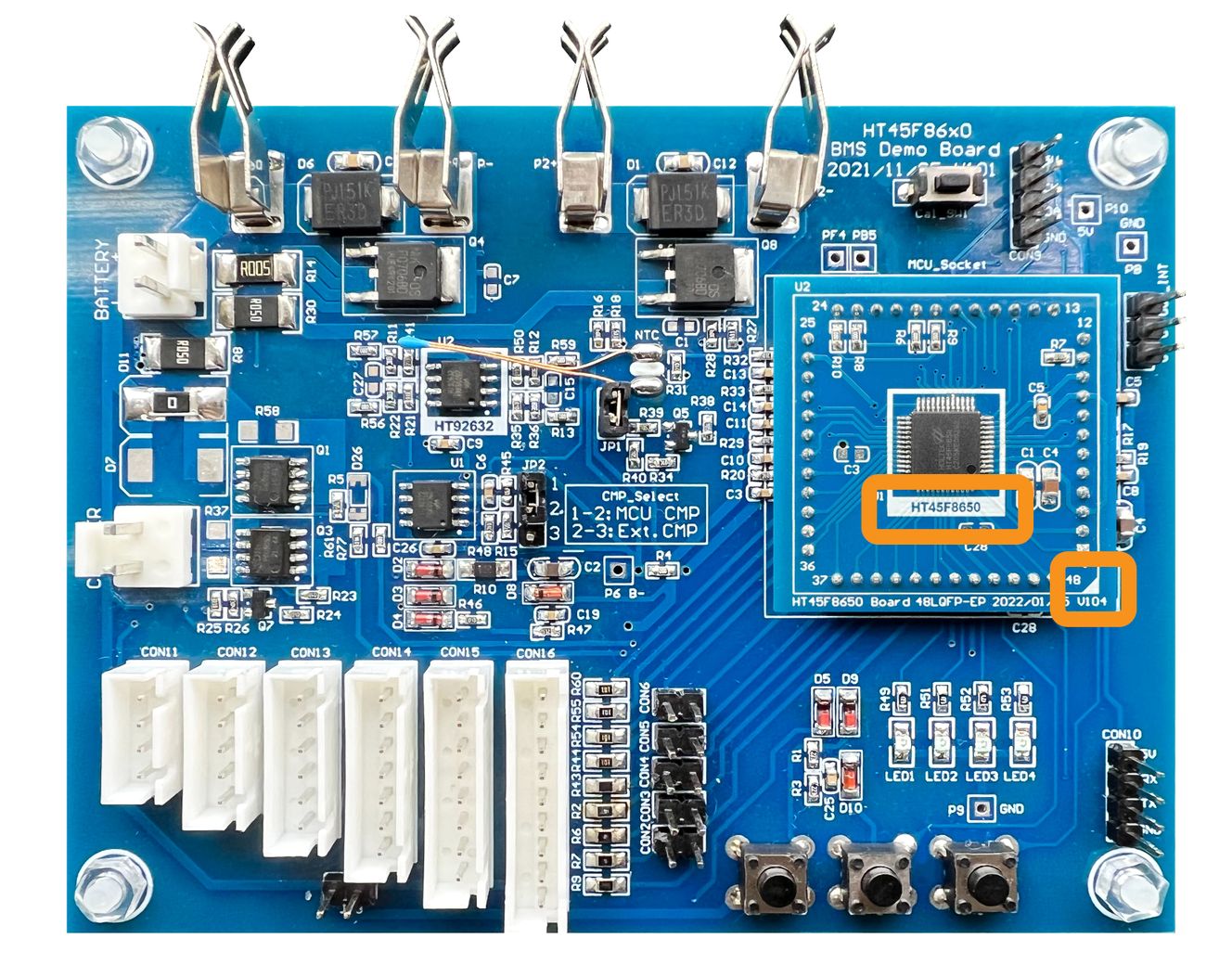

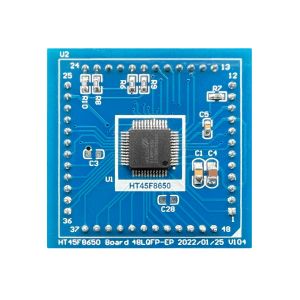

This product is a development board of the BMS Workshop to help you monitor the status of Li-ion batteries. It needs to use with the HT45F86xx series MCU adaptor board, the voltage calibration board, and the development platform, BMS Workshop, provided by Holtek.

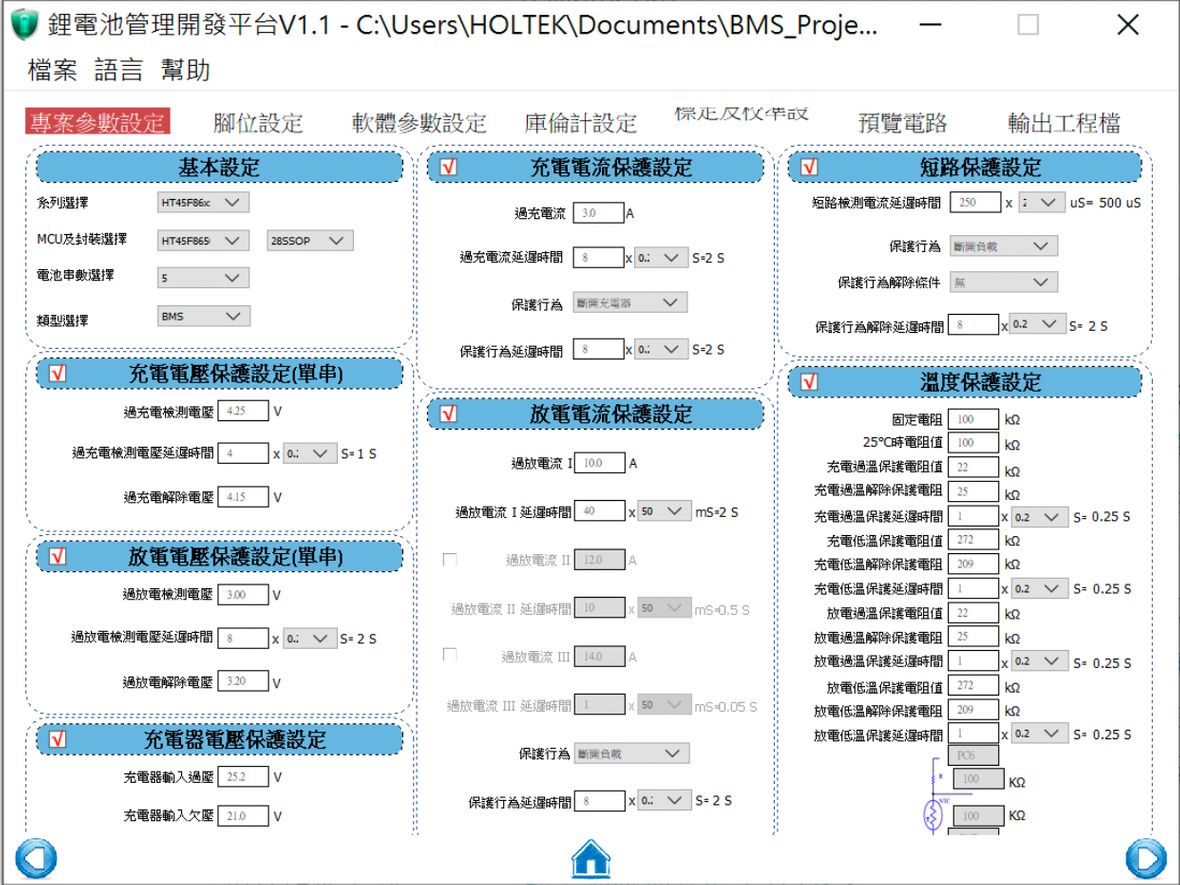

In the workshop, you can set multiple parameters and then generate program codes and schematics. Codes can be programmed into the MCU adaptor via e-Link and HOPE3000 for e-Link software.

BMS Workshop includes seven protection functions: charge protection, discharge protection, charger voltage protection, charge current protection, short-circuit protection, and temperature protection.

Product information

Dimension: 110 x 90 x 18 mm (PCB)

Net Weight: 51g